Inspections Explained

In previous articles we have touched on the Maintenance Pie where it clearly outlines that Maintenance is broken into three main areas:

- Preventative Maintenance

- Breakdowns

- Modifications

Out of these types, we established that Preventative Maintenance is the best option in ensuring that you get the most out of your equipment by reducing any factors that may lead to breakdowns and establish whether or not replacements are required.

Preventative Maintenance can be further broken down into

- Inspections

- That is, observing what is going

- Service and lube

- Looking at the basics that need to be replaced on your equipment

- Repair/Replace

- Time based form of maintenance

- Every two years you replace equipment and so on

Of these three, how can you minimize the loss in your business? By doing inspections.

What an inspection is, is basically saying, pick a frequency. Whether it be daily, monthly, and yearly where you will go into the area and perform checks on each bit of gear. At each piece of gear a number of different checks will need to be done.

Remember that the best part about inspections is doing the simple checks. Take for example an electric motor. A simple inspection on one would be to check to make sure that it is clean, stick your hand on either end and in the middle to see if it’s running hot.

When you do an inspections there are three main things that we can do

- Tasks

- Doing something

- Make sure you clean the motor

- Checks

- Is the motor noisy? Etc…

- Readings

- What’s the temperature

- Vibration

Encapsulate these three inside the inspections and they will help you to stay on top of your equipment’s maintenance by helping you identify whether or not more work needs to be done on them.

In MEX, setting up inspections is easy. Once you know what inspection you need to be carried out, set up the inspection and set a frequency. You then choose the assets you want to inspect and set the tasks, checks and/or readings that you need inspected.

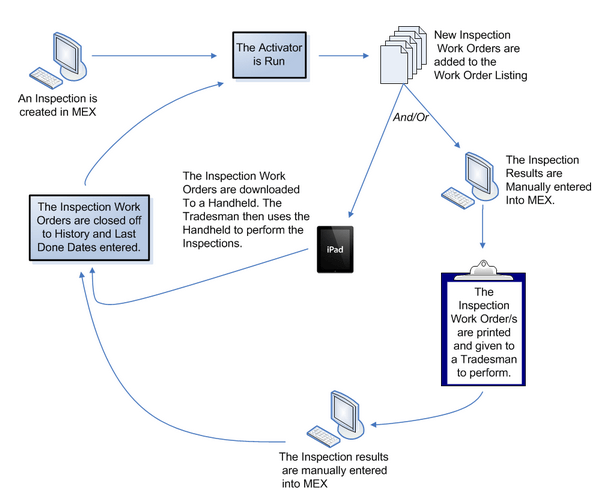

Once your inspection is due, an order is created and your maintenance personnel can carry out the inspection on paper or through the MEX iOS and Windows Surface apps.

Here is the work flow in MEX:

Would you use Inspections in your operations?

Stephen Ninnes

MEX General Manager

Google+

Resources

- Contact out support team at support@mex.com.au or call +61 7 3392 4777 for more information

- MEX iOS App