Preventative Maintenance Types in MEX

Preventative Maintenance is the module in MEX that will allow you to manage all your repetitive and routine jobs; for example three monthly, 100 hour, or 10,000 km servicing. There are different scenarios when dealing with the maintenance schedule of equipment. Some equipment need inspections and servicing done at set intervals, others depend on usage and some cannot be predicted.

The MEX Preventative Maintenance module uses four PM types to cater for each of these scenarios. These are

- Fixed

- Hierarchy

- Triggered

- Standard Jobs

Fixed

The Fixed PM type ensures that Work Orders are raised by the Activator at the set fixed intervals set on the respective PMs. If this option is selected, regardless of when the last raised work order is closed, MEX will push out the next work order on the set date. Not having this option selected allows for flexibility in the next due date. Giving the user the option to set a new due date upon closing the last raised work order.

Hierarchy

The Hierarchy PM type works with multiple Preventative Maintenance Schedules for the same Asset.

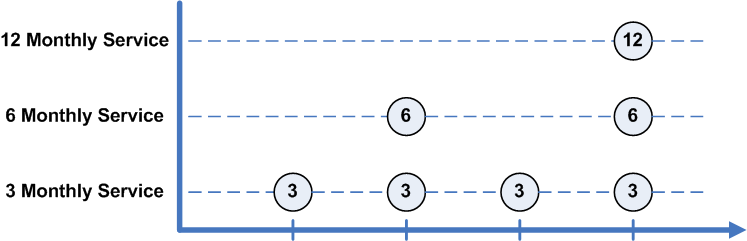

For example, an air conditioning unit may have three Preventative Maintenance schedules created for it. The policies might be for a three monthly service, a six monthly service and a yearly service. In the diagram below the three schedules can be seen generating their Work Orders at a three, six and twelve monthly interval.

With the Hierarchy option ticked on each of the three policies a degree of organization is imposed. When two or more Preventative Maintenance schedules are due to create Work Orders at the same time:

- The Preventative Maintenance schedules are sorted into a Hierarchy. The policy with the longest interval will be at the top of the Hierarchy, and the policy with the shortest interval will be at the bottom.

- Only the Preventative Maintenance on the top of the Hierarchy will create a Work Order, the remaining Work Orders will be suppressed.

- When the Work Order is closed off to History it will be assumed that the suppressed Work Orders have also been done.

Triggered

The Triggered PM type only raises a new Work Order for a schedule once the set reading on the Asset is surpassed and only works with readings based on frequency types.

In MEX the Date and Reading that a maintenance service is next due to be done is typically determined using a calculated average usage. Unfortunately, some equipment that has a usage that is so variable that it makes it difficult to come up with a meaningful average usage. For example, a truck that may operate 130 hours a week for 2 weeks straight and then may not work for the next 3 weeks makes it hard to determine when a 500hr service would next fall due. In this case, there may be a service scheduled for next week, so MEX will create a Work Order for this. However, the reality is that the service will not actually need to be done for about a month.

The Triggered option is intended to overcome this issue. If the Triggered option is set for a Preventative Maintenance, then the Preventative Maintenance will not create a Work Order until you actually enter a reading that takes you up to or past the next service point. That is, in the previous example, a reading that took you to 500hrs since the last service.

Standard Job

A Standard Job is a Preventative Maintenance that does not have a frequency associated with it. A Standard Job generates Work Orders when they are triggered manually, rather than according to a pre-defined schedule. They are a way of creating a template for a Work Order that is repetitive but cannot be predicted.