Adjusting Preventative Maintenance Hierarchy Last Done Dates

Preventative Maintenance (PM) plays a key role in ensuring that your assets are serviced at the right times. When adding new assets into MEX, you can run into situations where you need to skip a PM or start halfway through the regular A-B-C servicing. This article will be a quick guide as to how to adjust the last done dates/readings on the Preventative Maintenance policies in that scenario.

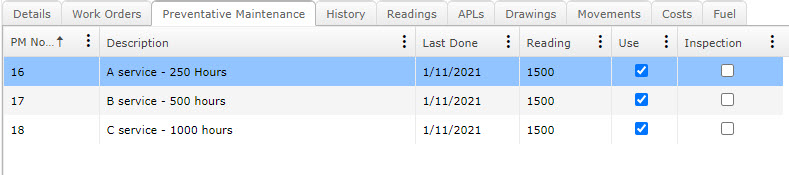

For this example, we will use a generator with different servicing requirements of 250, 500 and 1000 hours respectively. The generator in question isn’t new and recently had the 500 hour service done at 1525 indicated hours. You could also think of this as an asset that existed in the system and the last done readings just have not been set correctly.

Checking Assets Attached to All PMs in Hierarchy

The first part will be making sure the asset is attached to all of the PMs in the hierarchy.

- This is done with the normal method of going into the PM details and attaching the asset in the Asset Using tab.

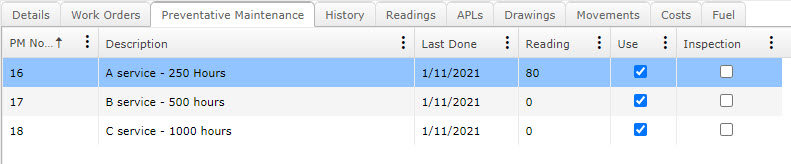

- At this point if we go to the Asset Register and look at the Preventative Maintenance tab we see something like this.

- Now we just need to figure out what the readings are meant to be and update them.

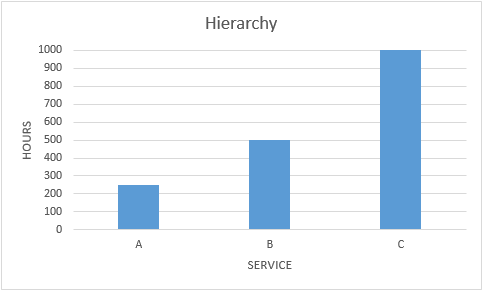

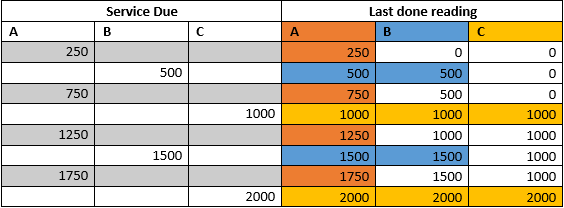

The chart above shows the current hierarchy intervals we are working around. This is important because for every work order raised from one of these service PMs, it will also set the last done reading to be the same for all of the related services falling under the same interval. The table below is to help illustrate how these dates are updated as the services are performed.

The idea behind this is that a 250 hour service will be due 250 hours after the last service so we want it to have the same last done date as the larger services so the correct Work Order/s are created at the intended time. Once you understand this, it also makes it easy to see which service was the last one performed and which service will be due next.

Setting Last Done Dates

Now that we understand how the dates work we can set the last done dates for our generator. The easiest way to do this is by doing the following

- Go to the Asset Register

- Select the asset you are after in the Asset Tree

- Click the Preventative Maintenance tab.

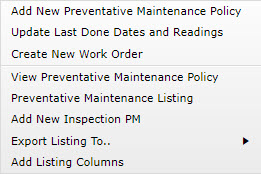

- If you right click in this listing you should get an option for ‘Update Last Done Dates and Readings’ as below

- On the screen that opens you can modify the last done dates for all of the PMs in the one spot instead of having to jump between the individual PM policies and updating the last done reading from the ‘Asset Using’ tab.

So here is what it looks like after modifying the last done dates.

Explanation: Last service was the 500 hour service at 1500 hours, which means the 250 hour service will have the same last done reading as it has a smaller interval. To figure out the 1000 hour service just work 500 hours back from the last done reading against the 500 hour service at which time the 1000 hour service would have been due.

Running the MEX Scheduler

Now this is all set and we can check it is working by running the Scheduler from the Preventative Maintenance listing.

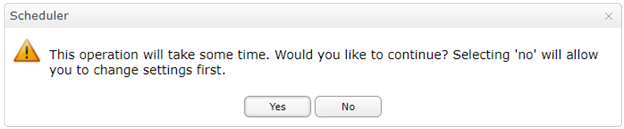

When you open the Scheduler, you will be given the option to automatically load all schedules straight away by selecting ‘Yes’. If you select ‘No’, it will allow you to change range options before populating the Scheduler. This is particularly useful for companies with a larger quantity of PMs.

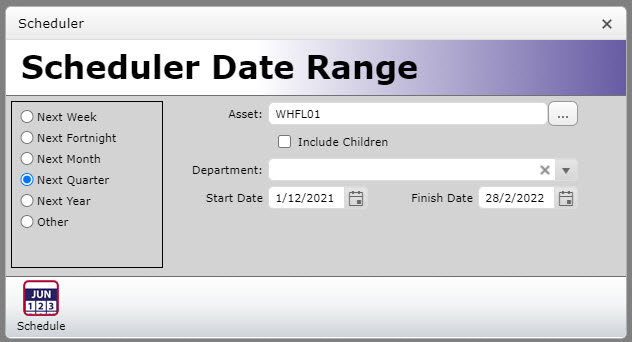

Now that you’re in the Scheduler, you can set the Schedulers parameters by clicking the ‘List’ button found near the bottom left corner of MEX.

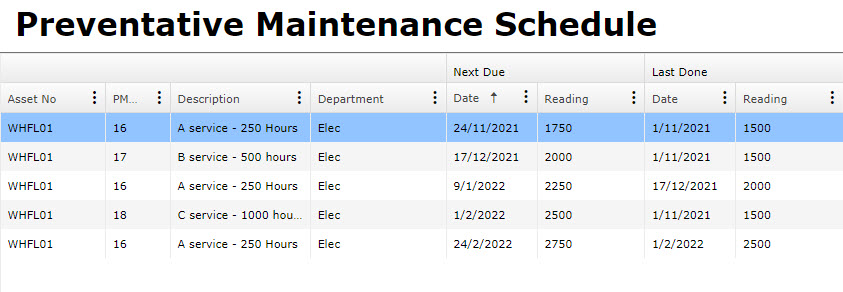

And here is the result. What matters here is that the services are raising in the correct sequence, the date is merely a best guess by using the average hours per week from any readings that are against the asset.

In a nutshell, this is how you adjust and monitor that the Last Done Dates of your assets assigned to a hierarchy are working correctly.

Any Questions?

If you have any questions in relation to this article about adjusting Preventative Maintenance hierarchy last done dates please contact the MEX Support team at support@mex.com.au or call +61 7 3392 4777.